Table of Content

Their materials is no longer within the part after sintering and this should be a consideration. Many of the detailed investigations of activated sintering have been conducted on tungsten. Tungsten with out special remedy reveals a high stage of porosity and is kind of weak.

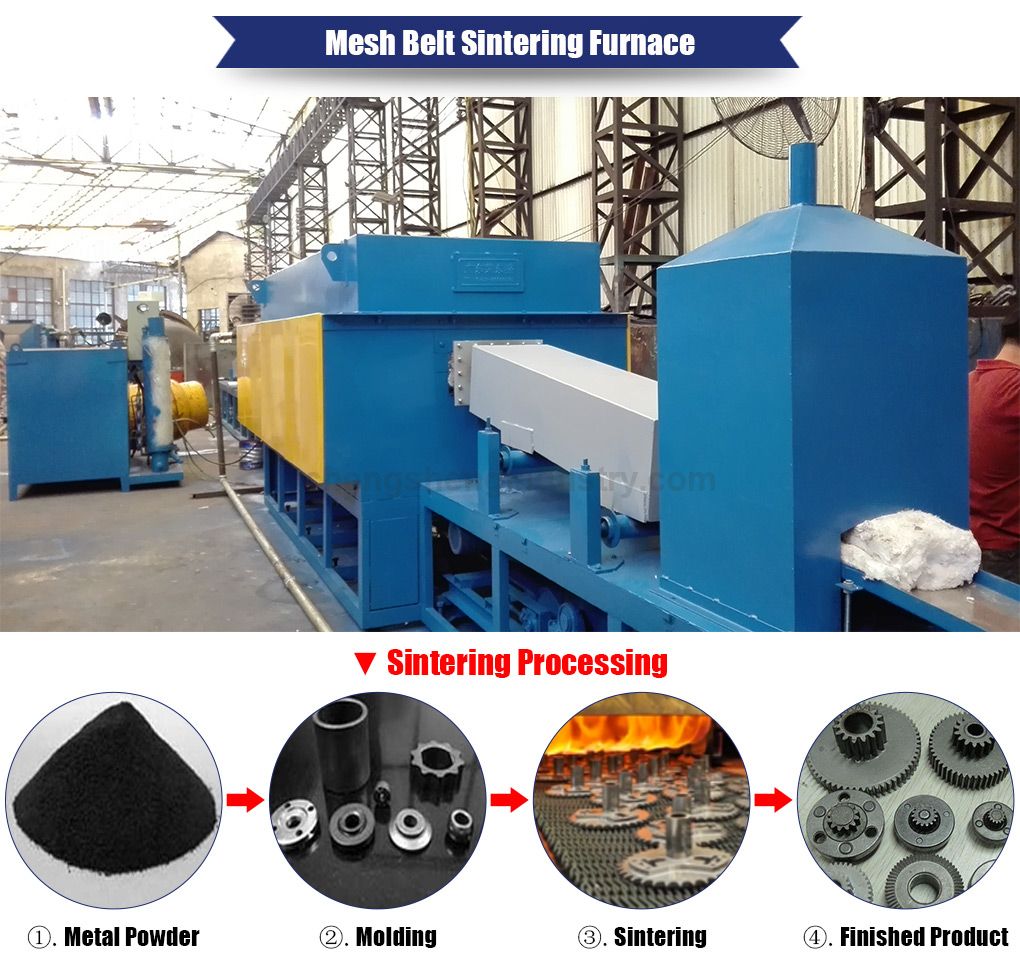

The second stage of the sintering process known as “the urgent phase”, and that is the moment during which the piece takes its form. The amount of dislocations noticed in HA and Si-HA samples have been related, but a significantly bigger number of triple points were observed in Si-HA samples in comparison with HA samples. Also, TEM imaging of these triple factors in an Si-HA ceramic containing 1.5wt% silicon showed the presence of a much less crystalline section at some of the triple junctions. Si-HA samples with lower levels of silicon were proven to have ‘clean’ grain boundaries, with no further phases current. The reliability of furnace operation is set by the lifetime of the conveyor belt, which is operated in conditions of elevated temperatures, mechanical loads and a corrosive environment. In business apply, oxidation or roasting copper powder is normally done in air at temperatures above 650°C.

What's Sintering?

You can discover complete content about supplies on this category. Energy Enery and vitality engineering is amongst the largest sector in mechanical engineering. You can find the vitality associated articles and contents of Mechanicalland on this class. Sintering know-how combines multiple processes to be mixed and accomplished in just some steps. Furthermore, this know-how is recognized as a green course of with minimal waste, with typically not more than 2-3% waste within the course of.

Surface processes similar to painting or electroplated are additionally used within the finishing of powder processed merchandise. As with different secondary and ending processes, the porosity of the work should be thought-about. Materials for surface coatings should not be absorbed into the porous structure of the work. Infiltration and impregnation of porous elements is often employed to permit for surface remedies.

More Assets On The Powder Metallurgy Sintering Process

Therefore, we've written this text to tell you, clearly and concisely, about what sintering is. Studies on the ultrastructure of Si-HA ceramics using transmission electron microscopy have additionally proven some delicate variations compared to HA. We set ourselves aside from competing OEMs by servicing our merchandise for the lifetime of the gear. While some companies attempt to boost new tools gross sales by retiring old ones, we never discontinue our gear providers, making certain you obtain optimal service life. Built to rigorous requirements using advanced applied sciences and materials.

A half is powder manufactured with about 15%-20% porosity, after which scorching solid. Hot forging eliminates porosity, rising the density of the half. Hot forging of the powder processed part additionally creates a uniform wrought grain construction. Secondary processing of a powder manufactured half by forging greatly enhances the mechanical properties of the half.

Partial Sintering

Sintered ultra high molecular weight polyethylene supplies are used as ski and snowboard base supplies. The porous texture allows wax to be retained throughout the construction of the bottom materials, thus providing a extra durable wax coating. Gasbarre specializes within the design and manufacturing of custom-engineered sintering furnaces specific to the thermal processing business. As an business leader in manufacturing solutions, we develop each sintering oven with high quality and reliability in mind. All of our merchandise exhibit their own revolutionary options, together with specialised features fit for any manufacturing facility.

This eliminates the vacancy formation vitality from the activation vitality for diffusion. Alternatively, therapies such as cyclic heating of a material similar to iron through the polymorphic section transformation represent a change within the driving drive. In the latter case, cyclic heating generates an inner stress, which successfully raises the driving drive.

Think About With Carbon

Ceramic powder compacts could be created by way of chilly isostatic urgent, injection moulding or slip casting, following which they are pre-sintered and machined to a ultimate shape before heating. There are three different heating methods for pressureless sintering - constant-rate of heating , rate-controlled sintering , and two-step sintering . The ceramic microstructure and grain dimension will differ depending on the material and method used. For device steels, microstructural problems typically precede significant distortion. M6C carbides type a eutectic liquid with the steel matrix throughout sintering. Upon cooling, extreme liquid pools from oversintering will solidify into grain boundary carbide movies or lamellar mixtures of carbide and metal, rather than discrete carbide particles.

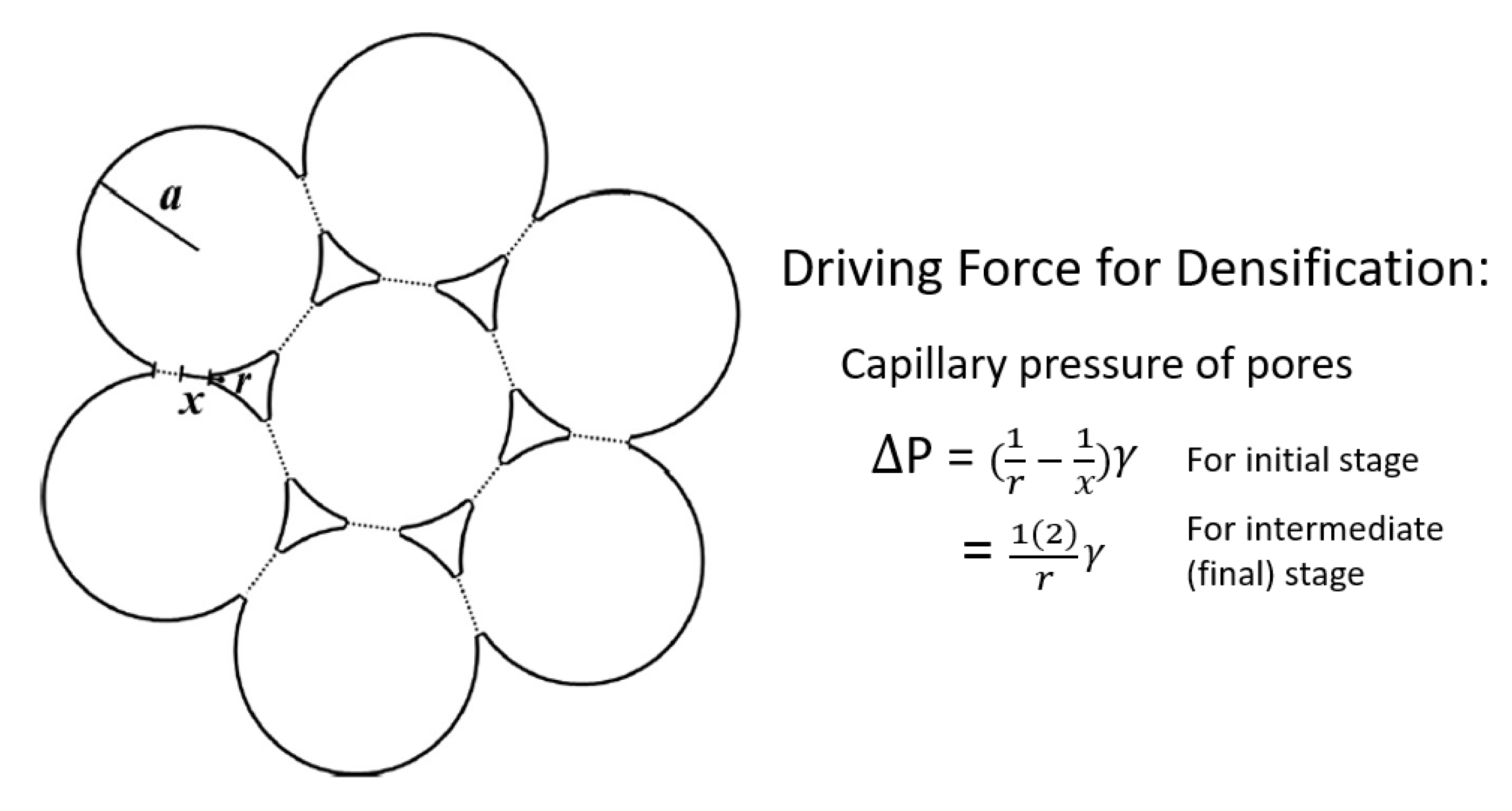

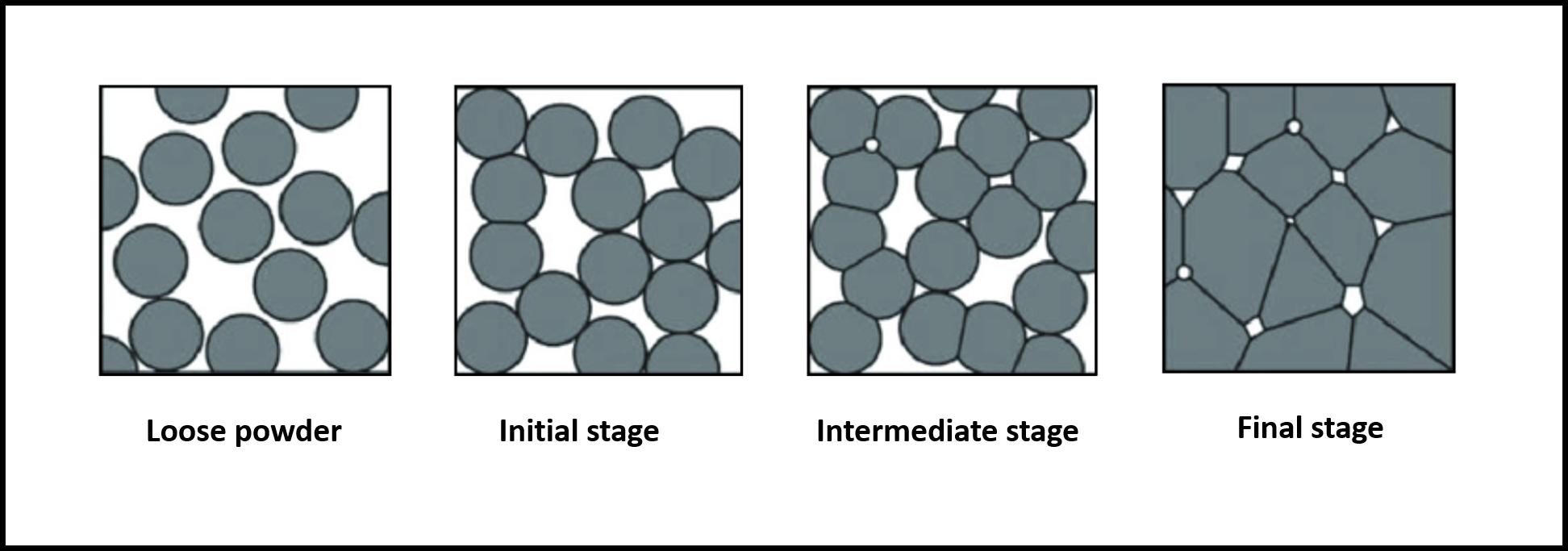

The densification process will increase the density of the sintered half to acquire a extra strong and rigid structure. To make the sintering operation easier, there are totally different additives are added within the mixing or blending step to steel powders. There are a variety of various methods depending on elements such as using electrical currents, pressure and warmth sources as properly as the precise materials being sintered. However, faster sintering times can result in lowered density and residual porosity.

This grain growth can either be normal or irregular, a traditional grain progress is characterised by the uniform growth and measurement of all the grains within the specimen. Abnormal grain growth is when a few grains develop a lot larger than the remaining majority. Sintering that uses an arc produced by way of a capacitance discharge to remove oxides earlier than direct current heating, was patented by G. This originated sintering strategies employing pulsed or alternating current, ultimately superimposed to a direct current. Those techniques have been developed over many decades and summarized in additional than 640 patents. Sintering of powders containing precious metals similar to silver and gold is used to make small jewelry objects.

A key benefit of sintering in powder metallurgy is the chance to create very complicated external shapes, and probably inner ones as properly. This is due to the truth that both the matrix that displays the exterior form, and the possible cellular punch placed inside to make a formed gap, are made by wire EDM with centesimal tolerances. This is achieved by a decreasing of the solidus temperature with a minimal lower within the upper-phase boundary limit that leads to extreme microstructural coarsening. It should be noted, nonetheless, that a change in carbon content material of this magnitude can affect the performance of the metal, and a change in grade may be a greater answer.

No comments:

Post a Comment