Table of Content

In industrial powder manufacture their are two kinds of furnaces, batch and steady. In a batch furnace low quantities of elements are positioned within the furnace, bear the whole sintering process and are eliminated. Continuous furnaces provide move by way of manufacturing and have three zones for the three levels of the manufacturing process, . A transferring belt carries a steady supply of parts by way of the chambers. Heat doorways can quickly open and close to allow elements through, whereas maintaining warmth in. The belt travels at the precise velocity to provide components the correct quantity of time in each chamber.

It may be concluded that Si3N4 is a multiphased materials consisting of mainly β- and α-phases of Si3N4, secondary grain boundary phases , and an amorphous film at the grain boundaries. All these phases have characteristic morphologies and could be arranged in all kinds of microstructures. Pressureless sintering is the sintering of a powder compact with out applied strain. This avoids density variations within the last element, which occurs with more conventional scorching urgent methods.

What Parts Are Made Utilizing The Sintering Process?

Another technique to create a extra uniform density within the pressed compact is to use extra punches with separate movements. Multiple action urgent of powders is frequent industrial apply with more advanced elements. Amount of powder wanted might be based on the bulk density of the powder and the amount of material in the ultimate half. Bulk density is mentioned in the previous section, it's the density of the free powder by itself. The effects of components corresponding to lubricants must always be calculated. For example, a green compact has a sure amount of lubricants and binders in it that add further material.

Such a therapy is analogous in some respects to external stresses with scorching pressing. The compacted half can be handled inside the manufacturing website to ship them to sintering operations. The bulk density is increased within the compaction process, which is calledgreen compact density. The manufacturing of pottery is the most common use for the sintering course of, used the world over. It has been utilized for hundreds of years in a single kind or another to strengthen clay supplies. Most individuals, however, are stunned to learn that powder metallurgy has an equally storied history courting again to the traditional Egyptians over 5,000 years ago.

More Question About The Powder Metallurgy Sintering Process?

Thus, it represents an environmental and economically attractive alternative. With a machine park geared up with several powder sintering machines, we are ready to reply to any additive initiatives, from prototypes to large series. Depending on materials and methods, sintering can take wherever from a few milliseconds to over 24 hours. The longer the ice sits within the water, the harder it's to interrupt those cubes up. The former sample exhibited comparatively excessive flexure strength near forty MPa for the excessive porosity of ~65%, which is five instances larger than that of the latter one.

Note how the rate of density improve drops off between the preliminary repacking stage and the second plastic deformation stage. Force for industrial powder manufacture typically varies between 10,000 lbs/in2, , and one hundred twenty,000 lbs/in2, . Parts for this type of manufacture are mostly small, , and press requirements are usually under 100 tons. Mechanical presses with capacities on the magnitude of a few hundred tons are usually enough for many powder processing operations. Hydraulic presses with capacities of a quantity of thousand tons are typically used for work requiring extra force.

Powdered Steel: What’s The Distinction Between Sintering And Melting?

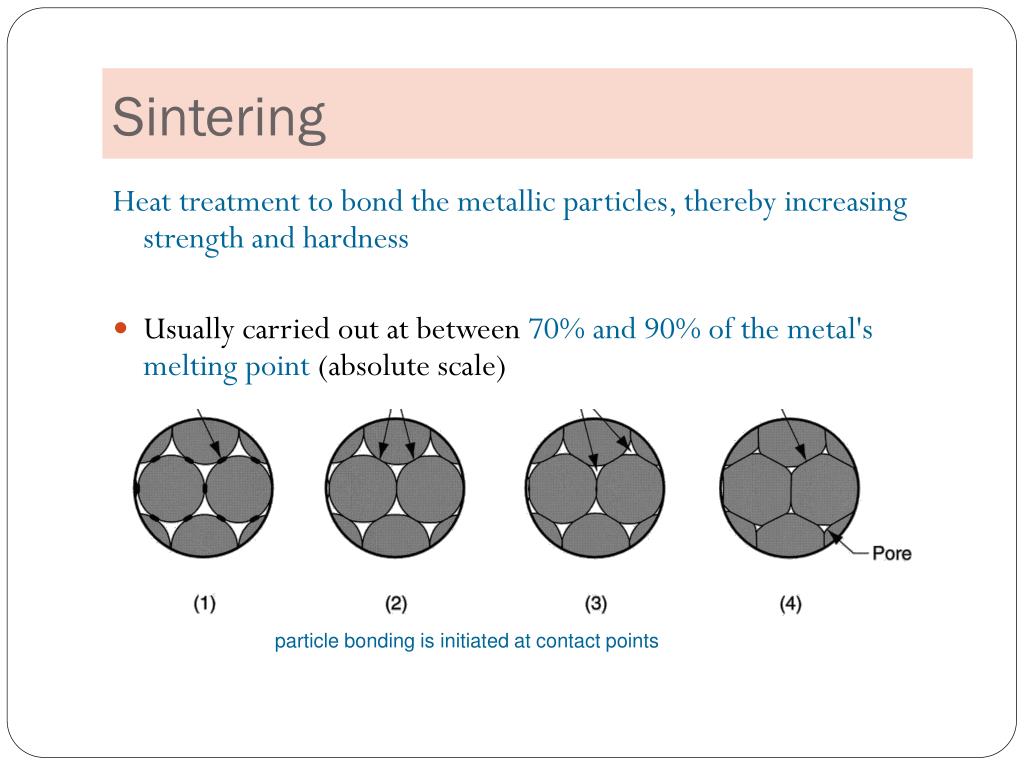

As sintering applied sciences have improved, the actual sintering supplies have also improved. The sintering powders used in the steel manufacturing process — stainless steel, aluminum, nickel, copper and titanium alloy — make up the overwhelming majority of powder metals utilized in additive manufacturing at present. Sintering, which is also known as ‘frittage,’ is the process of forming a strong mass of material by way of warmth and pressure with out melting to the purpose of liquefaction. This course of involves the atoms in materials diffusing across the particle boundaries and fusing together into one piece. Sintering occurs naturally in mineral deposits, and is used as a producing course of for supplies together with ceramics, metals and plastics. However, the oblique impact that silicon has on decreasing the grain dimension is an interesting phenomenon, and offers one other potential methodology of varying the properties of HA ceramics.

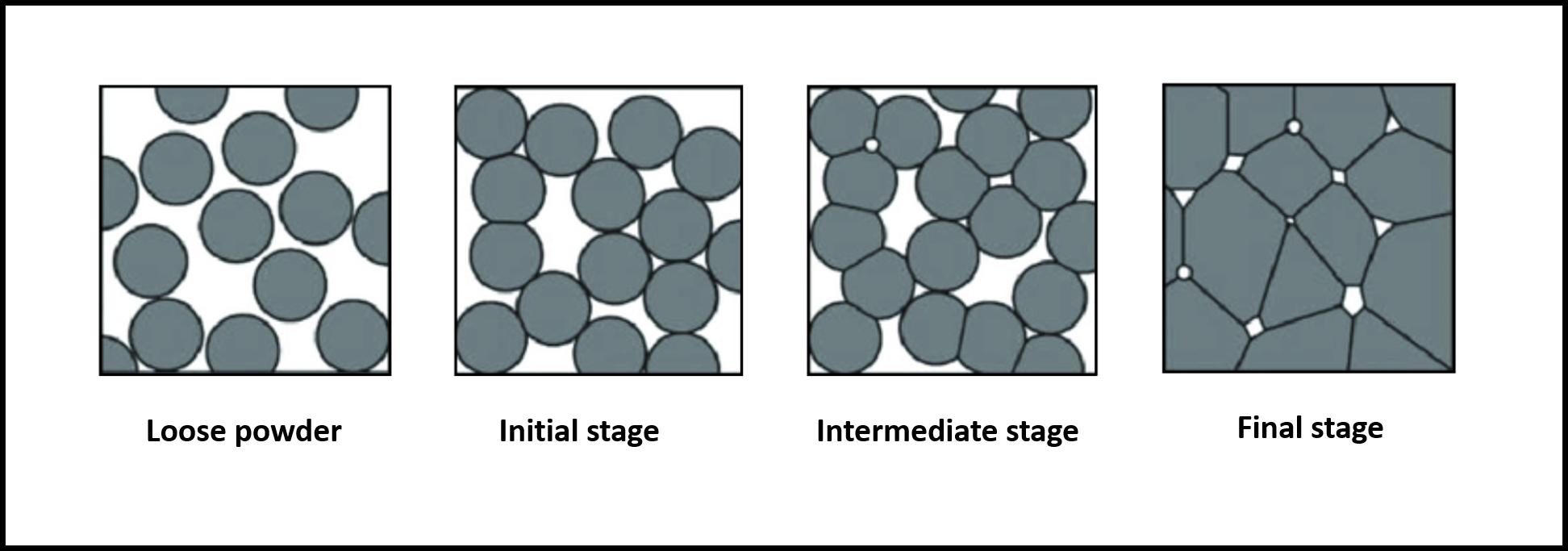

Liquid section sintering can eliminate porosity and produce parts with wonderful material properties. Interparticle pores and particle surfaces are an essential consideration within the urgent of powders. These supplies such as oxides could be rubbed off during pressing and occupy interparticular vacancies, stopping proper compaction of the half. In the primary stage of powder urgent density is elevated by a rearranging of the individual powder particles. Spaces, bridges and gaps are eliminated, and density increases as a outcome of a more environment friendly packing of the particles. This preliminary stage offers comparatively decrease resistance and the density of the powder quickly will increase with applied stress.

Powder metallurgy is mainly relevant to the auto business, gear manufacturing business, metal business, aerospace,... There are a number of kinds of superhard slicing supplies, and CBN is certainly one of these. SoftwareANSYS Mechanicalland guests can find a lot of articles and tips about ANSYS on illustrated foundation. ANSYS is explained in this category’s articles with pictures from ANSYS software. The advantage of the brake system is that it is only used when wanted.

Because of the printer's precision and swiftness, they've been a perfect selection for pharmaceutical firms. It can be used to rapidly produce extremely porous medicines and a range of immediate-release drugs and dosages. Its excessive accuracy helps within the production of complicated geometric tablets and polypills.

In these calculations, decrement between particle areas with compacting and sintering operations should be considered. First of all, the difference between the mixing and the blending of the steel powders. Blending is the blending of the identical steel powders with the assistance of a blending chamber. Blending is essential for the mixing of the different-sized metal powder particles homogeneously. Utilizing a sintering furnace, the “green” parts are heated to the suitable temperature to sinter the material. The temperature is beneath the required part’s melting level, but hot sufficient to attain the desired effect of tempering the metallic.

Sintering is characteristic within the burning off of components in the powder that had been essential for earlier processing stages. Elimination of constituents no longer wanted similar to lubricants, binders and deflocculates, is essential to hold up the purity of the fabric of the final product. In addition to rising the energy and density of the part's material, sintering also increases ductility, thermal conductivity and electrical conductivity. Shrinkage will happen throughout sintering, however might be calculated for when manufacturing course of components are managed.

No comments:

Post a Comment